Improved Vapor Recovery Unit

Category:

VOCs Substitution and Pollution Prevention Technology

Applicant:

SYSTEM ENG SERVICE CO.,LTD. Japan

Country:

Japan

Technology Overview:

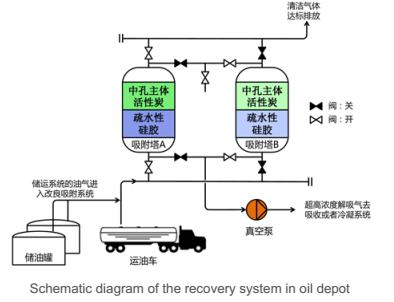

◎◎ Utilizes custom-made, noncombustible adsorbent (hydrophobic silicon) for selective

adsorption of VOCs, and separation of vapor components.

◎◎ VOCs components captured on the adsorbent could be released through the

process of vacuum pressure swing adsorption (VPSA), which uses vacuum pump to

decompress the adsorption tower, and then be liquefied for recycling and reuse. The

vapor gases with VOCs components removed can be discharged (reach emission

standards) or be reused.

◎◎ Hydrophobic silicon is noncombustible, which reduces safety risk on site. Comparing

with activated carbon, silicon possesses higher hardness and more stable crystal

structure.

◎◎ The adsorbent is hydrophobic silicon, utilizing special preparation process to remove

silanol groups on the surface, which enhances its affinity to oil and gas and reinforces

the strength of crystal structure.

◎◎ High heat capacity, low temperature rise by heat adsorption, and great adsorption

ability under high VOCs concentration.

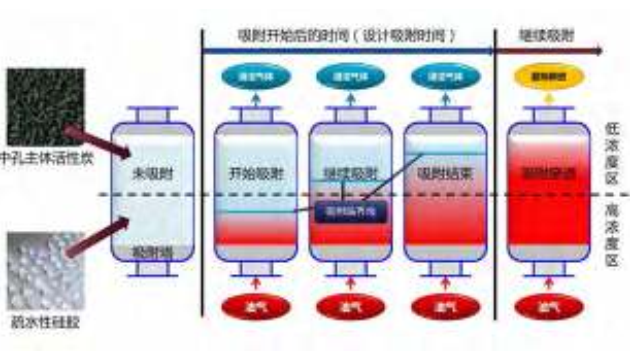

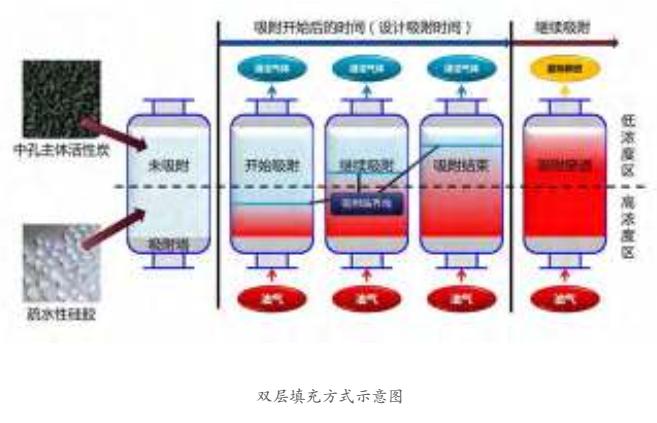

◎◎ Two layers of adsorbents are filled in the adsorption bed, with the upper layer of active

carbon and lower layer of silicon. The silicon layer contacts the gas vapor first, fully

utilizing its advantages of low termperatuter rise and great VOCs adsorption capacity

under high concentrations. Placing active carbon on the top layer helps to slow the

temperature rise, increase vapor adsorption at low concentrations and extend service

life. In case of higher safety requirements, active carbon could be replaced with mesoor micro-porous silicon, which further lowers the safety risk at site while maintaining

capture capacity.

Environmental Features:

Financial Features:

In view of the unit for gasoline vapor recovery ◎◎ The investment cost is about 3.8 Million Yuan for the unit with processing ability of 400m3/h. ◎◎ The investment cost is about 1.5 Million Yuan for the unit with processing ability of 100m3/h. ◎◎ The investment cost is about 2.5 Million Yuan for the unit with processing ability of 200m3/h. ◎◎ The investment cost is about 3.2 Million Yuan for the unit with processing ability of 300m3/h.

Implementation Status:

◎◎ PetroChina Henan Sanmenxia Oil Depot ◎◎ SinoPec Fujian Senmeishuibei Oil Depot ◎◎ SinoPecZhejiang Tongxiang Oil Depot ◎◎ SHAANXI YANCHANG PETROLEUM Yanan Refinery ◎◎ TIANJIN COSMO POLYURETHANE CO.,LTD (TCPC) ◎◎ Qingdao Lidong Chemical Co., Ltd.