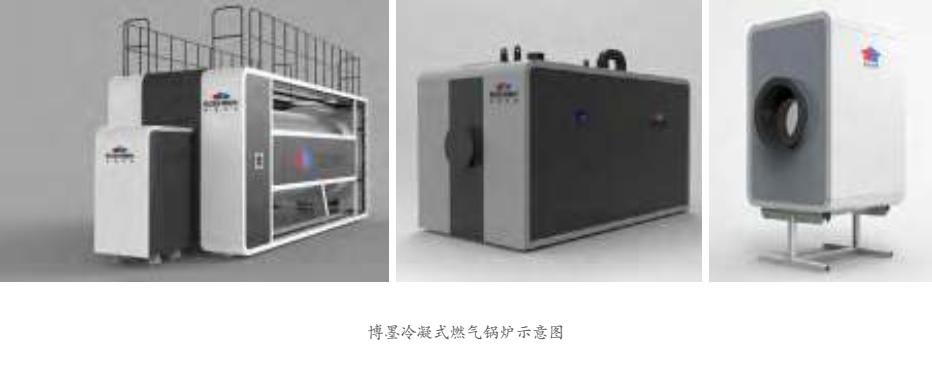

Integrated Condensing Gas Boiler Technology

Category:

Coal combustion emission control & clean energy substitutes

Applicant:

Suzhou Boehmer Thermo Products Co.,Ltd.

Country:

China

Technology Overview:

◎◎ Integrated gas-fired condensing boiler can recover thermal energy in flue gas in depth,

recovering sensible heat in flue gas and latent heat of water vapor condensation,

reducing heat loss from fuel combustion, improving thermal efficiency and cutting fuel

cost.

◎◎ Condensating water from fuel gas is beneficial for collecting harmful materials, and

reducing emissions of acid substances and other pollutants to the atmosphere.

Combined with low nitrogen combustion technology, the discharge of NOX can be

further controlled.

◎◎ The boiler applies enhanced heat transfer techniques at the fuel gas end, adopting

special designed condenser, to improve heat transfer efficiency.

◎◎ Self-cleaning through the special designed condenser, which encourages washing and

flushing of the heating surface by both flue gas and condensed water.

◎◎ Improves resistance to condensate corrosion by applying 316L stainless steel to the

boiler convective heating surface.

◎◎ Adopts single loop furnace design to lower flame temperature, minimize the generation

of thermal NOX, shorten the gas flow route, reduce total fuel gas pressure and cut the

power consumption.

Environmental Features:

◎◎ High energy efficiency: the integral design of the gas-fired boiler could reach condensation state within wide scopeof working conditions and make the best of waste heat from flue gas. Test report shows that thermal efficiency of the boiler remains at 97%-105% when the power output of the boiler changed from 30%-100% output, which saves fuel and reduces carbon emissions. ◎◎ Low NOX emission: as a result of the integrated design, emissions of NOX can reach 47.83mg/m3 without low nitrogen burner according to the test report.

Financial Features:

◎◎ Investment: initial investment for the equipment is 20-30 Yuan/m2 and initial investment for the system is 40-50 Yuan/m2. ◎◎ Payback period: for equipment is 1-2 years, and for the system is 3-5 years.

Implementation Status:

◎◎ In 2016, 4 BW2800 boiler were applied in Jinan University for heating. NOX emission is less than 50mg/m3. Thermal efficiency achieved 105.03%. ◎◎ In 2016, 2 WNS8-1.25-Q and 1 WNS10-1.25-Q boiler applied in Guangdong Shaoguan Guorun Tobacco Factory. Natural gas consumption for a tone of steam: 74Nm3/m2. ◎◎ In 2017, 6 BW2800 was applied to Ji'nan Greenland international city for Residential heating. ◎◎ In 2017, 3 BW7000 was applied to Beijing Xinzhuang for Residential heating. ◎◎ In 2017, 4 BW2800 was applied to Shanxi for Residential heating.